Biodiesel is a domestically produced, renewable, biomass-based alternative to petroleum diesel fuel. It’s made from a growing number of sustainable feedstocks through a process known as transesterification. Using biodiesel increases energy security and resiliency, improves air quality and reduces greenhouse gas emissions. It also provides a number of safety benefits because it is non-toxic, biodegradable and non-flammable.

The finished product is a high-quality mono-alkyl ester fuel that meets the ASTM D6751 specification and is approved for blending with renewable diesel, petroleum diesel, or a blend of renewable diesel and petroleum diesel at any level (ex. 20% biodiesel, 20% renewable diesel, 60% petroleum diesel).

Biodiesel Blends

Biodiesel blends are commonly defined as a blend of biodiesel and petroleum diesel identified by the level of biodiesel content in the form of BXX. For instance, B20–a common blend throughout the United States–is a fuel blend consisting of 20% biodiesel and 80% petroleum diesel.

Blends of biodiesel and renewable diesel are typically identified by the level of renewable diesel and biodiesel content in the form of RXX-BXX. For instance, R80-B20–a common blend in California–is a fuel blend consisting of 80% renewable diesel and 20% biodiesel.

B5 is a common biodiesel blend consisting of 5% biodiesel and 95% petroleum diesel. B5 is common in the United States thanks to government incentives. The fuel blend meets ASTM D975, which is the standard specification for diesel fuel and renewable diesel.

B11 is a common biodiesel blend consisting of 11% biodiesel and 89% petroleum diesel. B11 is widely available in Illinois and Iowa because of strong in-state tax incentives. In 2018, 85% of retail sites in Illinois were found to be marketing B11 and higher blends of biodiesel.

B20 is the term used to describe a blend of 20% biodiesel and 80% petroleum diesel. B20 is commonly found in Illinois, Minnesota, and Iowa thanks to in-state incentives and standards. B20 is the minimum biodiesel blend considered to be an alternative fuel by the U.S. Department of Energy’s Clean Cities program.

B99 is a readily available blend of 1% petroleum diesel and 99% biodiesel. B99 is more widely available than pure biodiesel (B100) as a result of Federal policies for blending and selling biodiesel, known as the biodiesel blenders credit (BTC)

Feedstocks

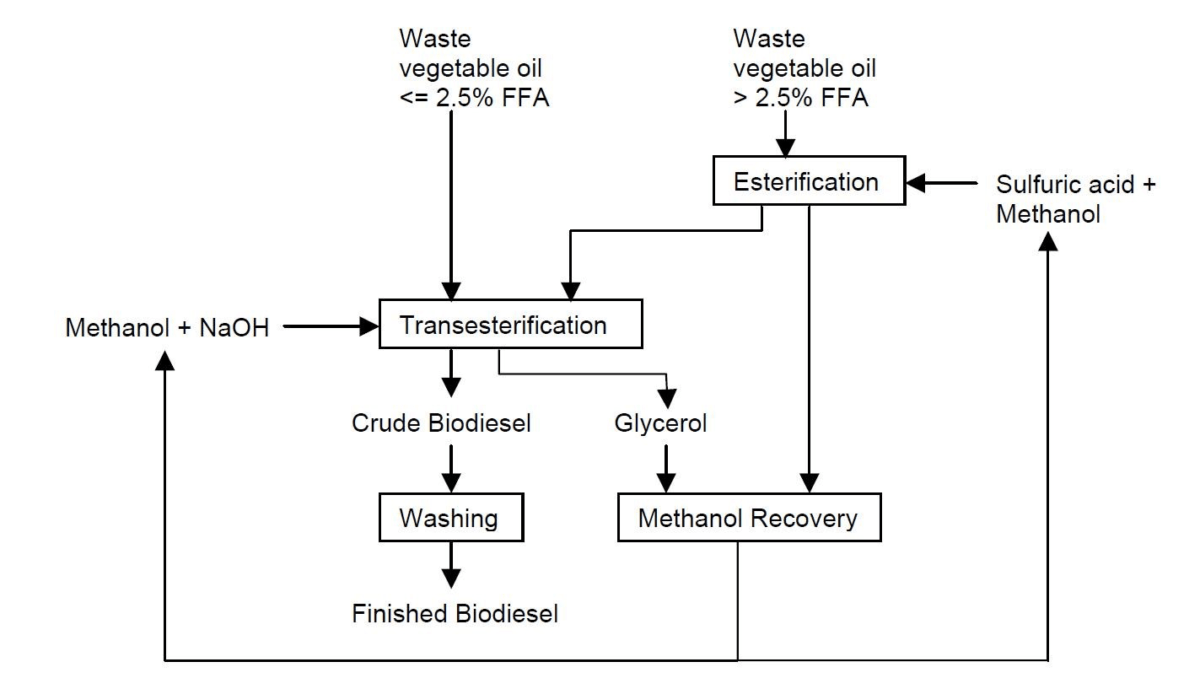

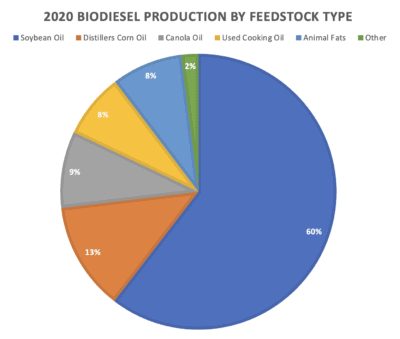

Biodiesel is produced from a diverse group of low-carbon, sustainable feedstocks, including soybean oil, used cooking oil, distillers corn oil, animal fats, and more. The feedstock ratios used recently are as follows:

Production

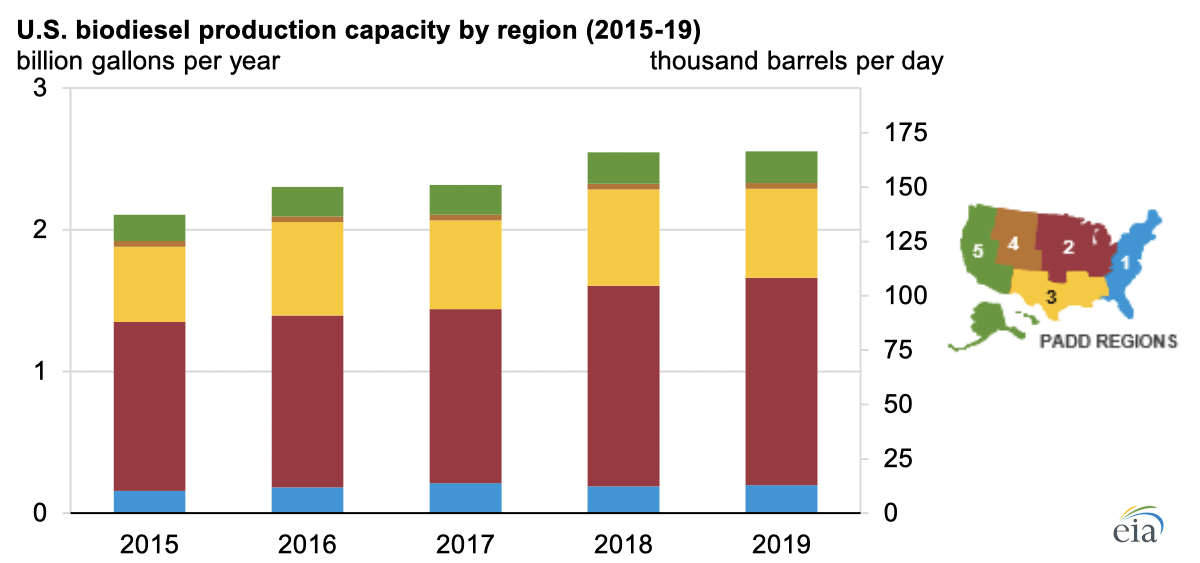

According to the 2019 U.S. Biodiesel Plant Production Capacity Report produced by EIA, the United States has 102 operating biodiesel plants with an installed annual production capacity of more than 2.6 billion gallons. More than half of the nation’s biodiesel production capacity is in the Midwest (PADD 2) region, led by Iowa, Missouri, Illinois, and Indiana.

ASTM Specifications

- Pure biodiesel (B100) meets ASTM D6751 and is approved for blending with renewable diesel and petroleum diesel at any percentage.

- Biodiesel blends up to B5 meet ASTM D975, the specification for petroleum diesel fuel and renewable diesel.

- Biodiesel blends of B6-20 meet ASTM D7467.

- Biodiesel blends above B20 (B21-B99) require that each fuel meet its respective ASTM standard, meaning the biodiesel must meet ASTM D6751 and the petroleum diesel or renewable diesel must meet ASTM D975 prior to blending.

Energy Security & Balance

According to the U.S. Department of Energy (DOE), the transportation sector accounts for approximately 30% of the total energy demand and 70% of the petroleum consumption annually in the United States.

Thanks to advancements in domestic extraction and refining techniques and widespread integration of alternative fuels and technologies, like biodiesel, the U.S. imported approximately 3% of its petroleum in 2019. Using biodiesel and other alternative fuels and advanced technologies to reduce fuel consumption continues to strengthen national security and reduce transportation energy costs for businesses and consumers.

According to USDA, soy-based biodiesel has a positive energy balance, meaning that biodiesel produced from soybean oil yields 5.56 units of energy for every unit of fossil energy consumed over its life cycle.

Air Quality & Climate

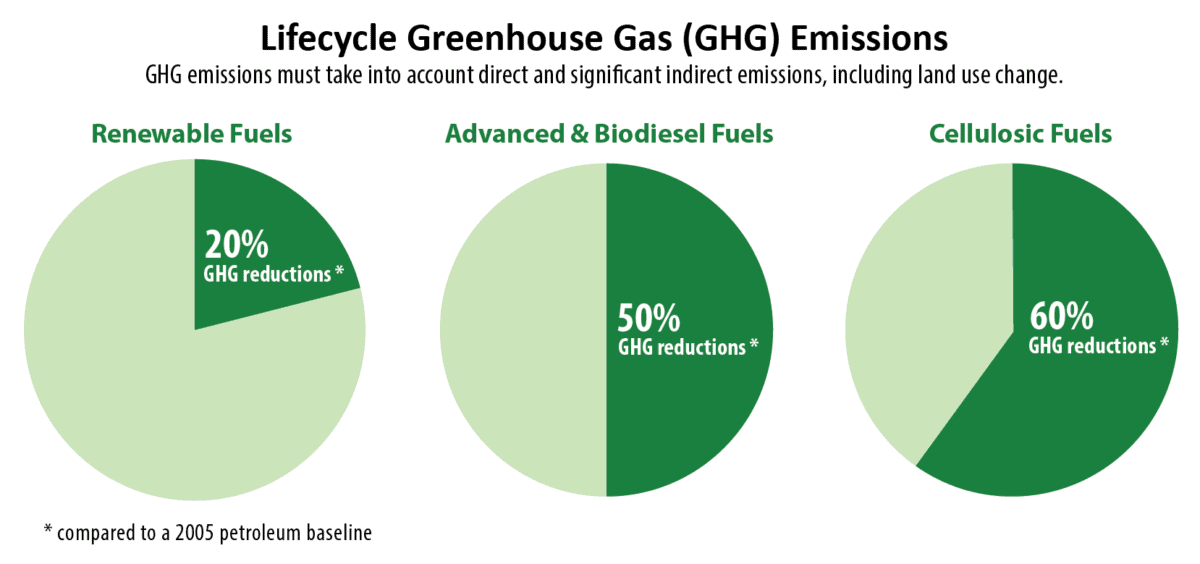

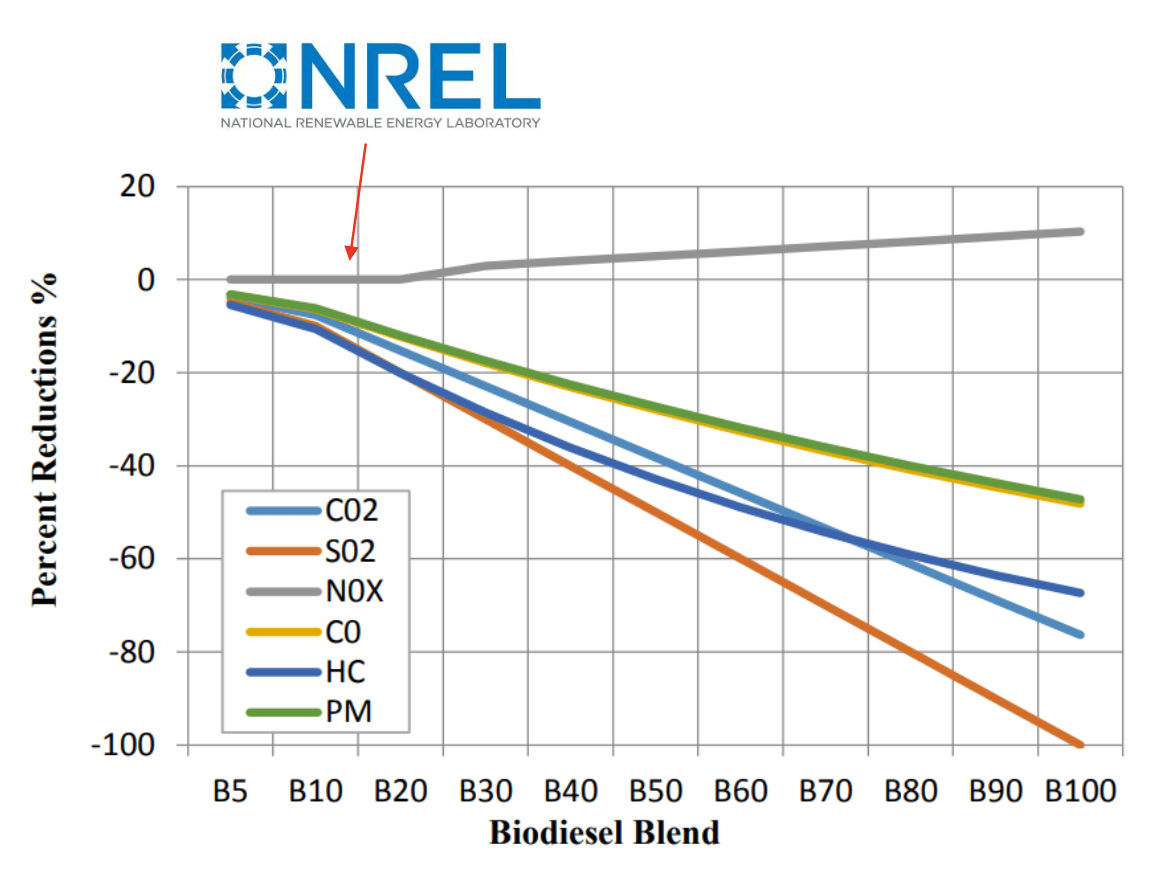

Using biodiesel reduces life cycle carbon emissions because the carbon released from biodiesel combustion is offset by the carbon dioxide absorbed from growing soybeans or other feedstocks used to produce the fuel. Life cycle analysis completed by Argonne National Laboratory found that B100 use reduces carbon dioxide emissions by 74% on average compared to petroleum diesel. The California Air Resources Board (CARB) reported similar values from various sources for its life cycle analysis of biodiesel while the USEPA found that biodiesel reduces lifecycle emissions by 57-86% compared to petroleum diesel.

Source: USEPA

The air quality benefits of biodiesel vary based on the level of biodiesel used. For instance, B20, a blend of 20% biodiesel and 80% petroleum diesel, reduces particulates by 10% and carbon monoxide by 12% compared to pure petroleum diesel fuel.

Engine Operation

Biodiesel improves fuel lubricity and raises the cetane number of the fuel. Diesel engines depend on the lubricity of the fuel to keep moving parts from wearing prematurely. Biodiesel can increase fuel lubricity in petroleum and renewable diesel fuels at blend levels as low as 1%.

Safety

Biodiesel in its pure, unblended form poses far less of a risk than petroleum diesel if spilled or released into the environment.

Biodiesel is less toxic than table salt and degrades as fast as sugar.

Biodiesel is also safer to handle than petroleum diesel with a flashpoint higher than 217°F (130°C), compared with about 125°F (52°C) for petroleum diesel.

Contact us with questions.

Indigenous Energy is a renewable fuels and energy consulting firm that partners with stakeholders to promote and advance the use of biodiesel and other sustainable alternative fuels, energies, and technologies.